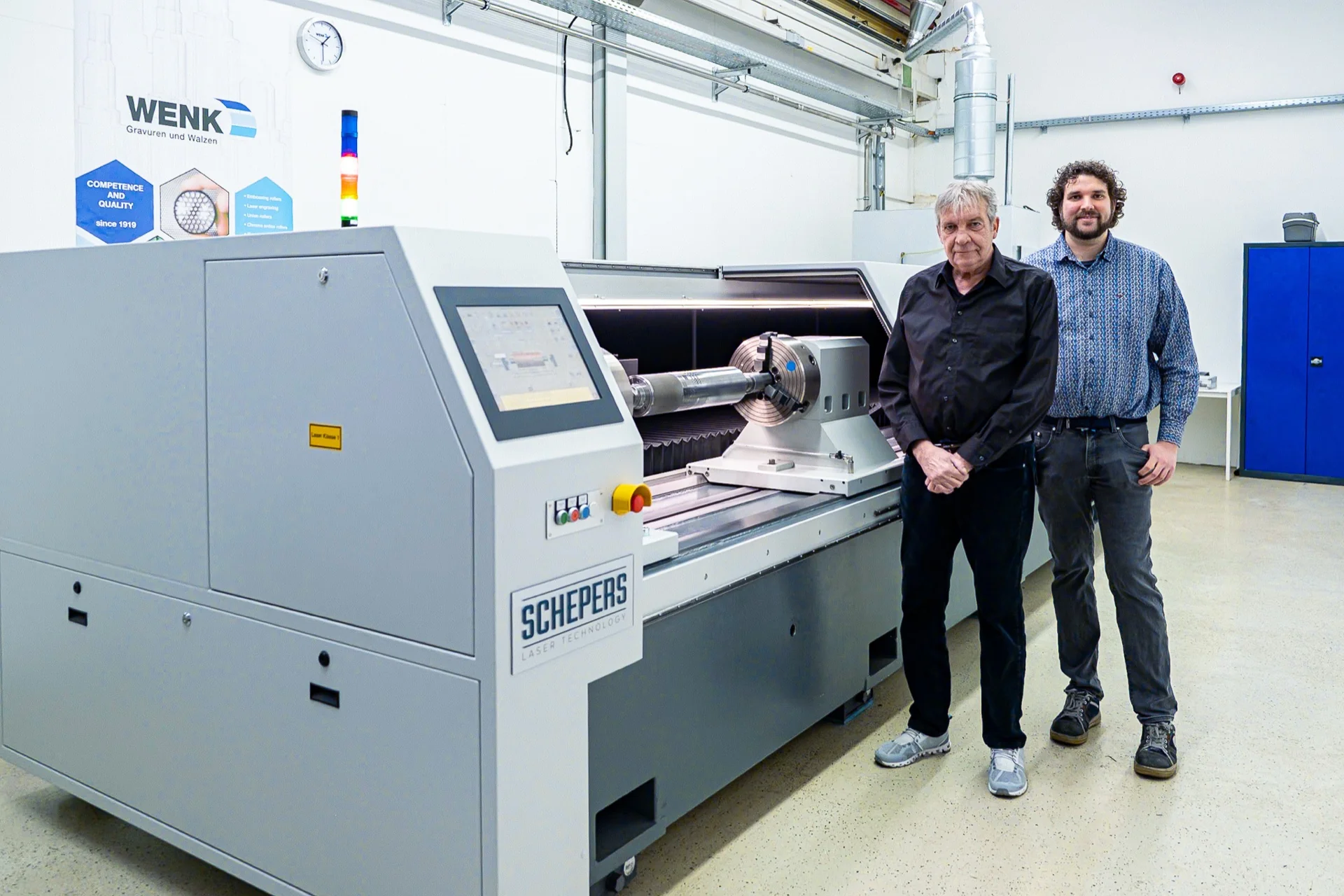

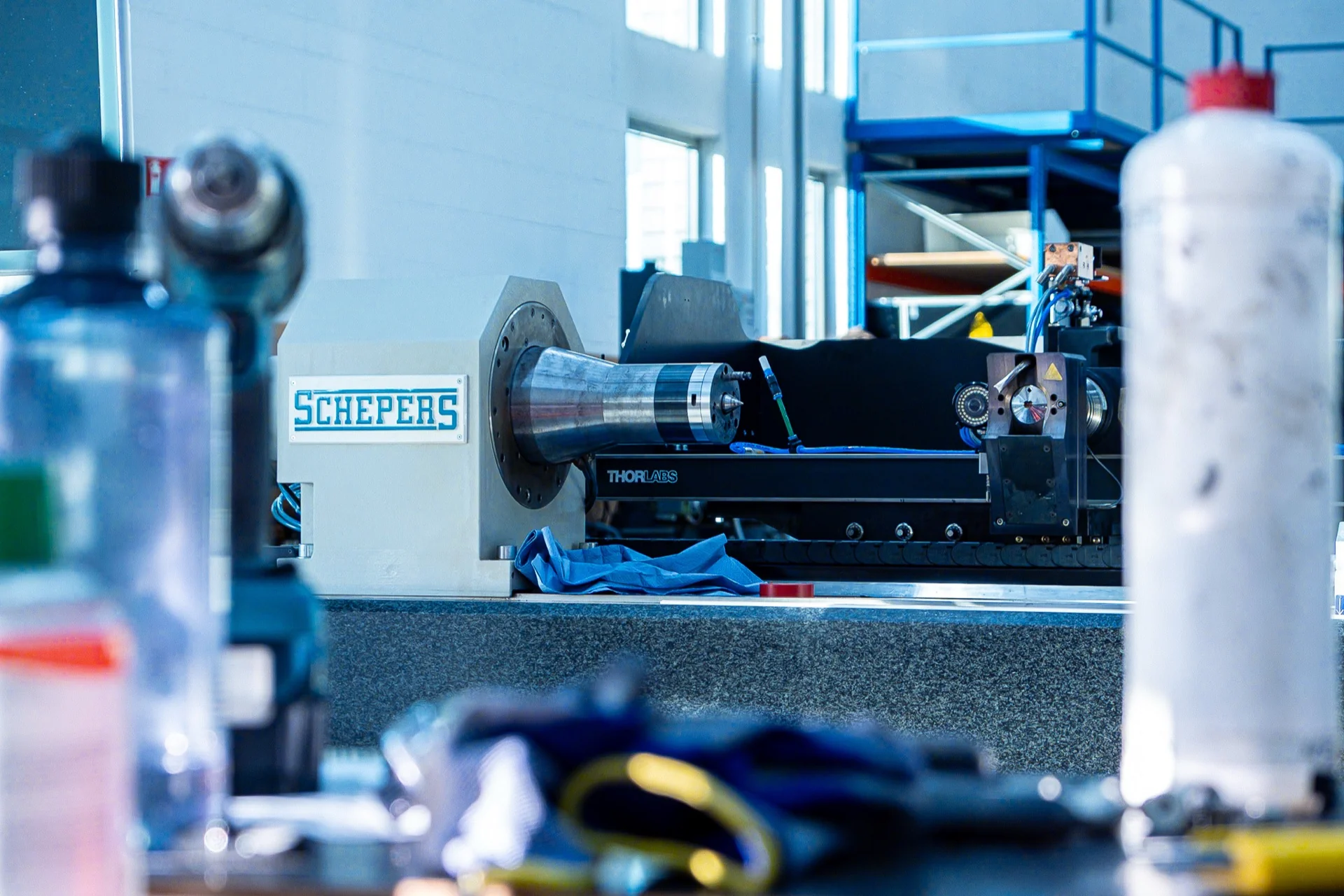

Pioneers in Laser Technology

Since 1991, we've been at the forefront of laser technology innovation, providing high-tech solutions for structuring printing, embossing, and decor cylinders. With 320+ laser machines across 37 countries worldwide.

The Schepers Advantage

Modular Design & Rolling Release

Our modular machine design allows us to fit products to the customer, not the other way around. This customer-focused architecture ensures you always get the latest technology without waiting for new versions.

- Highest quality-to-performance ratio on the market

- Modular design fits products to customer needs

- Latest technology at purchase - no waiting for next generation releases

- Field-upgradable components for maximum investment security

- Scalable systems that grow with your production demands

Multi-Vendor Laser Excellence

We select the technically perfect laser solution for each application, working with multiple manufacturers to deliver uncompromising quality. Our excelent mechanics and modern technology set us apart from the competition.

- Superior mechanics and modern technology than competitors

- Best-in-class laser sources from multiple manufacturers - no compromises

- Extensive experience with ultra short pulse laser systems

- Unmatched engraving quality on specialized rotary tool applications

- Technology-agnostic approach ensures optimal results for your specific needs

Complete Production Solutions

From laser engraving to etching systems and specialized software – everything you need for precision cylinder production.

Heliolas

Modern economical laser engraving system for cylinder production with unmatched price to performance ratio.

Learn more →

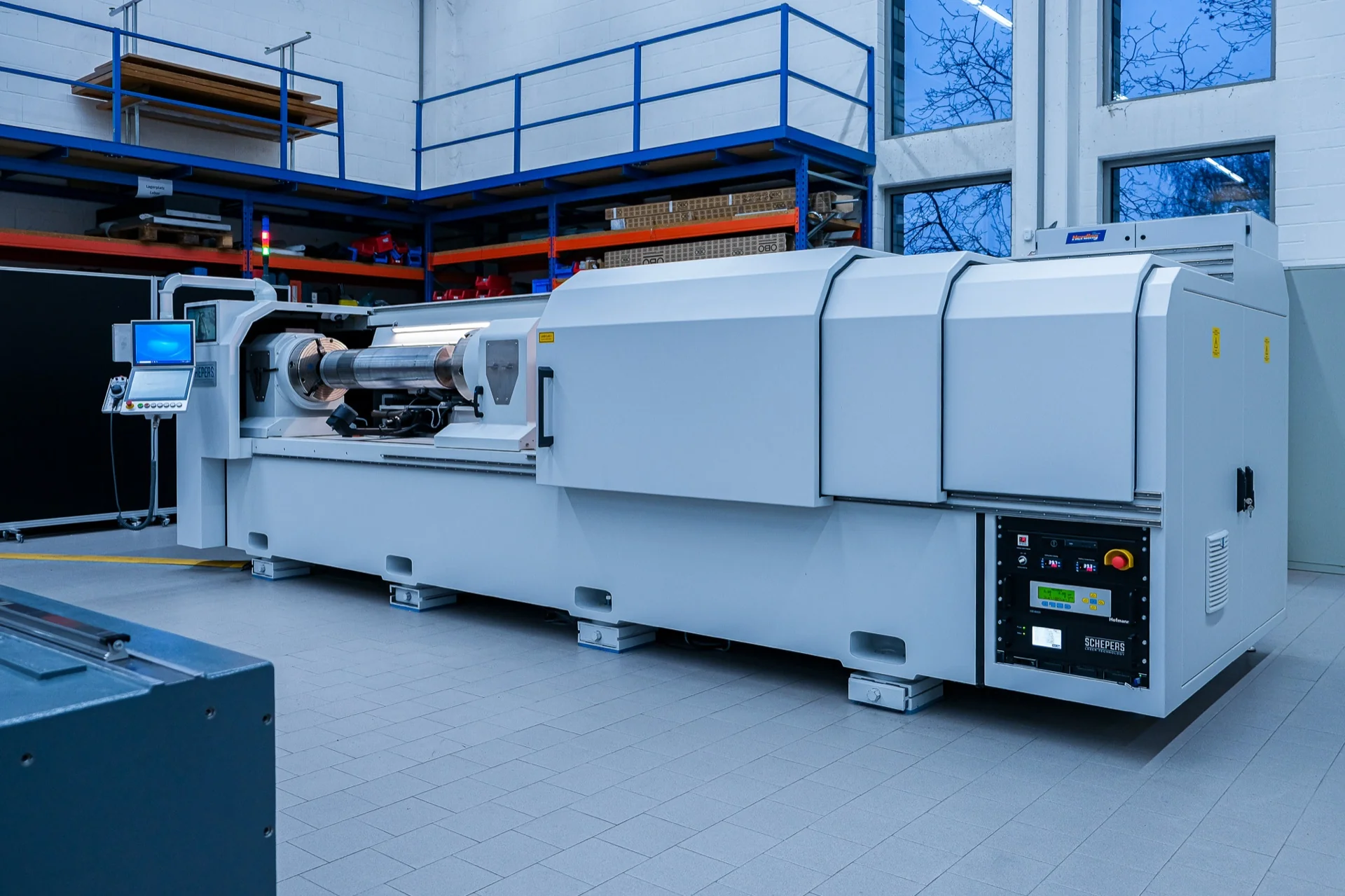

Digilas

High-end laser systems for direct and indirect engraving with exceptional accuracy, repeatability and performance. Scaled to your exact specifications.

Learn more →

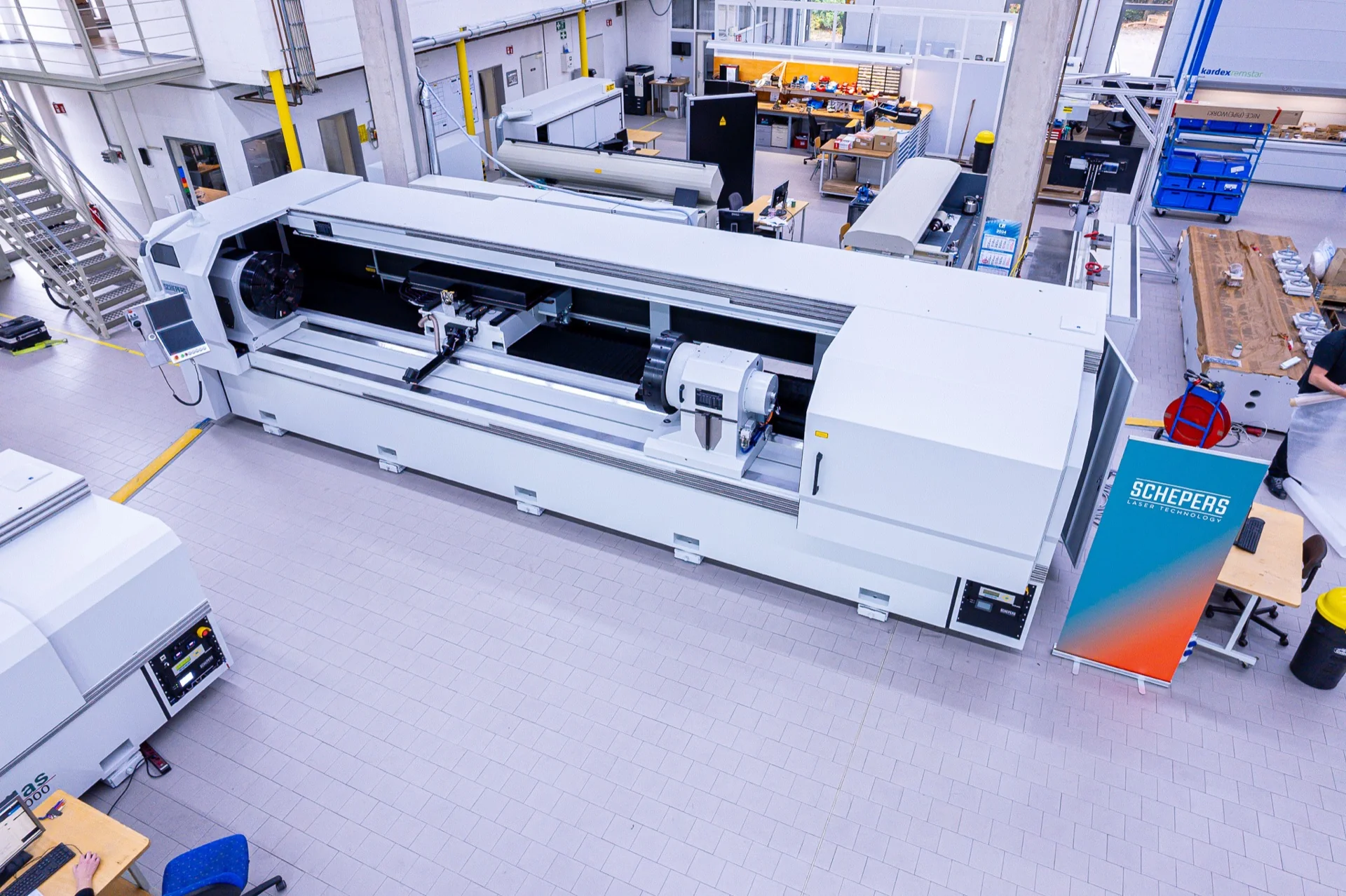

Digilas CE

Custom tailored laser engraving systems designed to meet every of your specific production requirements for all industries.

Learn more →True MultiBeam Technology

MultiBeam is the backbone to our success—allowing us to scale quality while maintaining nearly identical results. Beam count directly correlates to speed: a 4-beam setup is approximately 4 times faster than single beam. This revolutionary technology sets us apart, featuring up to 8 individually controlled laser beams (16 beams in development with select partners) with equal power distribution across all beams.

Beams Currently Available

Scalable from 1 to 8 beams—choose 1, 2, 4, or 8 beams based on your production needs. Each beam is fully independently controlled, allowing unprecedented flexibility and productivity. (Number of available Beams can be limited based on Application)

Beams in Development

Our next-generation system with 16 individually controlled beams is already in development, pushing the boundaries of what's possible. This will open a new world of performance for large embossing cylinder applications as well as ultra high demanding ultra short pulse laser applications.

Engineering Excellence

Our laser technology combines German engineering precision with innovative software solutions to deliver unparalleled engraving quality.

What Sets Us Apart

Precision Engineering

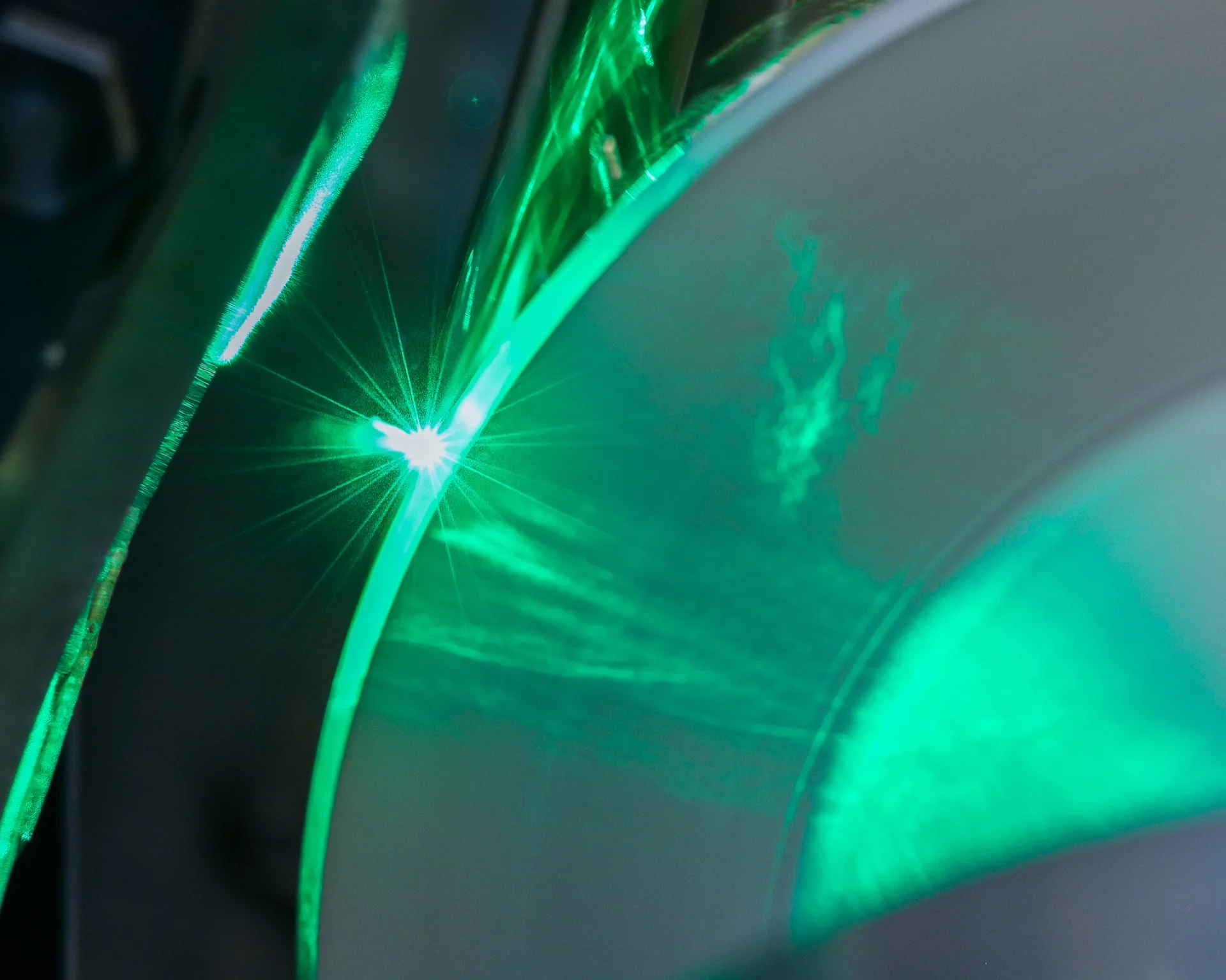

Micron level accuracy with advanced beam control technology for the finest detail reproduction.

High-Speed Processing

Industry-leading engraving speeds without compromising quality or precision.

Material Versatility

Compatible with diverse materials including metals, polymers, and composite substrates.

Dry Chamber Process

All Engraving Steps are fully dry which allow us to have easy switching between multiple applications in a short period of time hence cleaning is very easy and fast between engravings if necessary at all.

In-Line Brushing Process

Our Systems have an internal brushing system that thanks to the dry engraving process is working while the laser process is running. This results in a best possible use of time for maximum result quality. (additional brushing runs can be added)

Self Cleaning Exhaust

We use a solid-state filter unit with an automated self-coating solution which is not only fire retardant but also easy and safe to handle. Only the used powder needs to be replaced regularly, everything else will be handled by the system itself automatically.

Extensive Application Support

Our highly skilled technical and application team brings years of experience serving and supporting market leaders across every field. We provide comprehensive application support in nearly every industry, ensuring optimal results for your specific requirements.

Full Etching Technology Range

We are proud to still offer a complete range of etching technology for the printing and embossing industry. Our expertise includes comprehensive etching training and dedicated application support to ensure your success with traditional etching processes.

Complete Indirect Engraving Workflow

Seamless indirect engraving process: (1) Cylinder coating with SPB/VTB systems, (2) Lacquer removal via Digilas laser on surfaces to be etched, (3) Precision etching in SPM machine, (4) Cleaning in RUE station, (5) Chroming bath finish. Complete production line or individual components available.

CE Compliant & Safety Certified

Full CE compliant with all safety standards fulfilled. Our systems meet rigorous European safety requirements, ensuring the highest level of workplace safety and regulatory compliance for your operations.

Comprehensive Warranty & Support

Every system includes a 12-month standard warranty with business hours technical support. Startup and basic training are included with every installation. Application training and installation services are available upon request. Maintenance contracts ensure long-term reliability and peace of mind for your investment.

See the Difference

Micron-level precision that transforms embossing, printing, and anilox applications

Micron-Level Precision

3μm spot size for ultra-fine details

Perfect Surface Finish

Consistent quality across all cylinder dimensions

Production Ready

24/7 reliability for high-volume manufacturing

German Engineering

Premium components for superior performance

Trusted Across Industries

Top markets: Embossing, Anilox, Security, and Special Applications - serving leading companies worldwide

Contact

Reach out to discuss your requirements